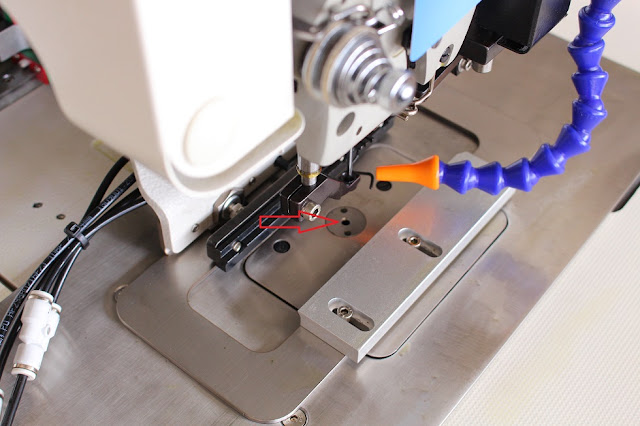

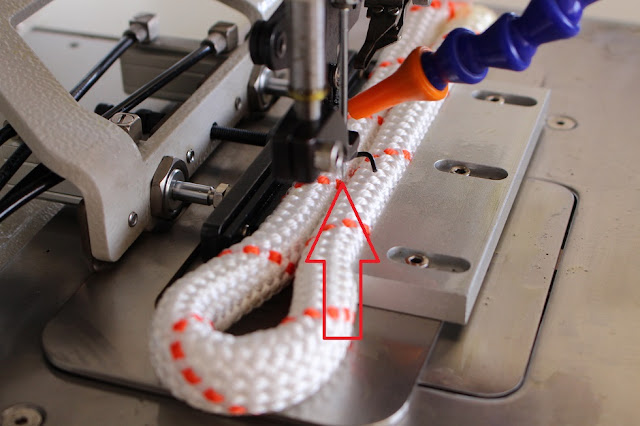

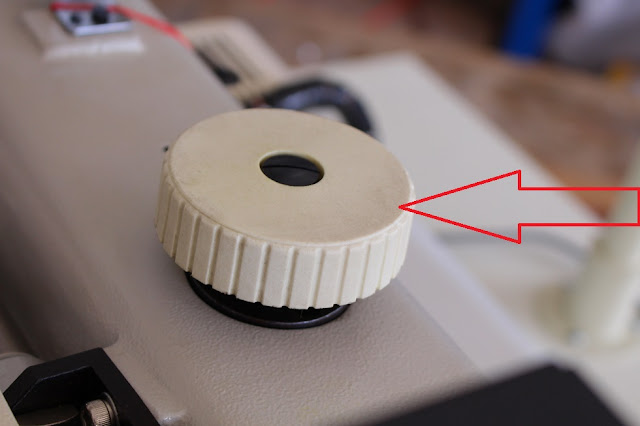

As dramatic as it may be, jamming is a very common problem for a sewing machine. Your first step toward a remedy is to remove any fabric you were trying to sew. This may require gently tugging at the fabric and lifting it enough that you can snip at the threads and pull the fabric free of the machine. Next, remove all the jammed thread; this may require removing the bobbin, the throat plate, and any other parts to release any jammed threads and get the machine sewing again.

Before you start sewing again, check your sewing machine needle. Even a slightly bent needle can cause a thread jam.